Feature

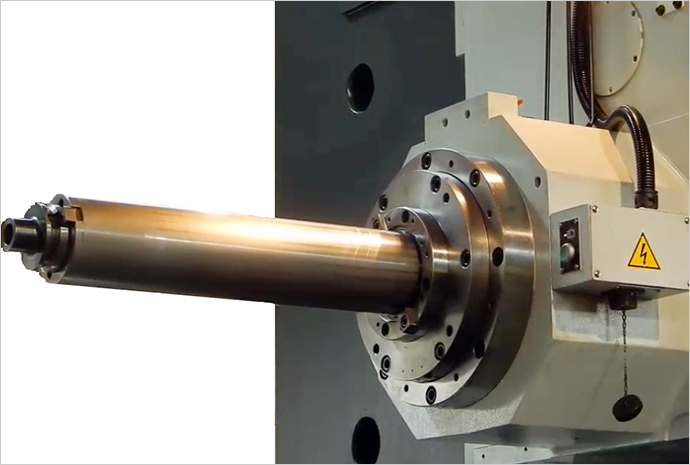

Spindle 135

- The specially designed spindle outer ring cooling system maintains constant bearing accuracy under normal operating conditions.

- This gear type auto-shift design and grease lubrication system also provides superior machine performance and reliability.

- The spindle and boring bar are made of SACM645 alloy. The spindle has been Nitrided to HRC62~68. This hardness maintains spindle form and insures high reliability. This increased rigidity increases the overall machine capability.

- We use the high quality spindle bearings to ensure machine consistency and a longer machine life.

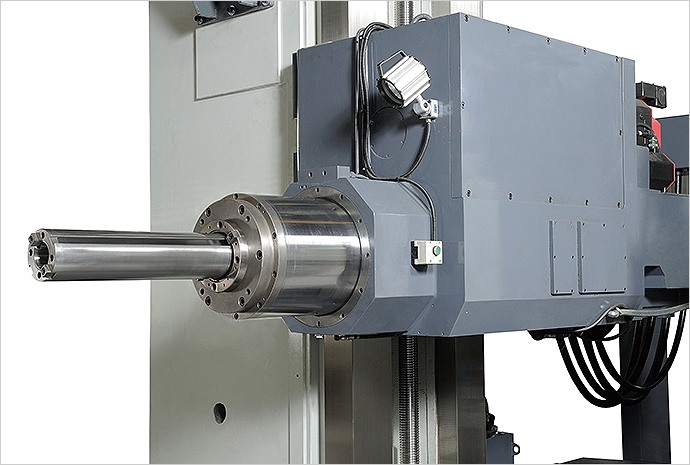

Spindle 135P (without Quill)

Spindle 135P (without Quill)

Facing head FH-700 (option)

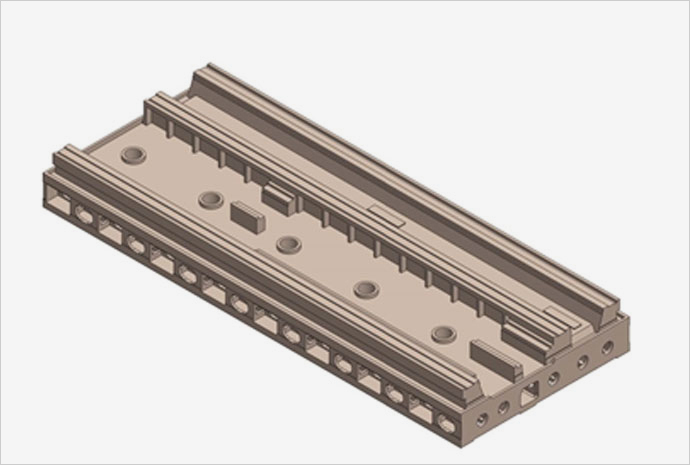

X & Y Axis Box Way

X & Y axis are box way, these highly rigid box way structures give you the very best machine durability. The material is high-frequency-heat-treat for stress relief, the hardness reach HRC 43-47 degrees.

Z Axis Linear Guide Way

The Z axis adopts three-rail linear guide way design to reduce friction and stick slip during sliding.

Rotary Working Table

The bed slideway is box way, adopted roller bearing and worm-gear equipped force lubricated system. Table center equipped Heidenhain rotary encoder assure index accuracy. Table equipped Hydraulic clamping system & positioning pin, assure indexing angle 0°, 90°, 180°, 270° heavy cutting accuracy.

CBA-135TR2

| Specification | Unit | CBA-135TR2 |

| Spindle |

||

| Main motor (Cont./30min) | kw | 37 / 45 |

| Spindle speed (Max.) | rpm | 2000 |

| Spindle taper | ISO 50 / BT 50 | |

| Spindle diameter | mm | Ø135 |

| Max. spindle torque | Nm | 2150 |

| Travel | ||

| Table cross travel X axis (Horizontal) | mm | 2000 |

| Spindle travel Y axis (Vertical) | mm | 1800 |

| Column moving travel Z axis | mm | 1100 |

| Spindle travel W axis | mm | 700 |

| Distance from spindle nose to table center | mm | 1045 - 2145 |

| Distance from spindle center to table surface | mm | 0 - 1800 |

| Rotary working table | ||

| Table size | mm | 1400 × 1600 |

| T-Slot | mm × No. | 22 × 9 |

| Max. loading weight | kg | 8,500 |

| Min. index | degree | 0.001 |

| Max. rotating dia. | mm | 2126 |

| Table rotation speed | rpm | 0.8 |

| Feed | ||

| Rapid(XYZW axis) | mm / min | XY axis = 8000 Z axis = 5000 W axis = 3000 |

| Feed rate(X Y Z axis) | mm / min | 1 - 5000 |

| Feed rate(W axis) | mm / min | 1 - 3000 |

| Machine size(L×W×H) | mm | 7450 × 7610 × 5260 |

| Machine weight | Kg | 39500 |

| Controller | Fanuc / Siemens / Heidenhain |

| Standard accessories |

Optional accessories |

| Tool and tool box |

Automatic tool changer |

| Foundation screw and bolt | Work table |

| Spindle oil cooler | Coolant through spindle |

| Spindle counter weight device | Linear scale |

| Working lamp | Spindle support |

| Electro cabinet cooler | Facing head |

| X axis dust cover | Angular milling head |

| Y axis dust cover | Universal milling head |

| V axis dust cover | Transformer |

| MPG | Splash guard for rotary table |

| Auto lubrication system | Splash guard for operator |

| Screw chip conveyor | Workpiece measuring device |

| Steel belt chip conveyor with cart | Spindle Quill (W2) 350mm |

CBA-135TR3

| Specification | Unit | CBA-135TR3 |

| Spindle |

||

| Main motor (Cont./30min) | kw | 37 / 45 |

| Spindle speed (Max.) | rpm | 2000 |

| Spindle taper | ISO 50 / BT 50 | |

| Spindle diameter | mm | Ø135 |

| Max. spindle torque | Nm | 2150 |

| Travel | ||

| Table cross travel X axis (Horizontal) | mm | 3000 |

| Spindle travel Y axis (Vertical) | mm | 2300 |

| Column moving travel Z axis | mm | 1400 |

| Spindle travel W axis | mm | 700 |

| Distance from spindle nose to table center | mm | 1045 - 2445 |

| Distance from spindle center to table surface | mm | 0 - 2300 |

| Rotary working table | ||

| Table size | mm | 1600 × 1800 |

| T-Slot | mm × No. | 22 × 9 |

| Max. loading weight | kg | 10,000 |

| Min. index | degree | 0.001˚ |

| Max. rotating dia. | mm | 2408 |

| Table rotation speed | rpm | 0.8 |

| Feed | ||

| Rapid(XYZW axis) | mm / min | XY axis = 8000 / Z axis = 5000 / W axis = 3000 |

| Feed rate(X Y Z axis) | mm / min | 1 - 5000 |

| Feed rate(W axis) | mm / min | 1 - 3000 |

| Machine size(L×W×H) | mm | 8300 × 7700 × 5760 |

| Machine weight | Kg | 43000 |

| Controller | Fanuc / Siemens / Heidenhain |

| Standard accessories |

Optional accessories |

| Tool and tool box |

Automatic tool changer |

| Foundation screw and bolt | Work table |

| Spindle oil cooler | Coolant through spindle |

| Spindle counter weight device | Linear scale |

| Working lamp | Spindle support |

| Electro cabinet cooler | Facing head |

| X axis dust cover | Angular milling head |

| Y axis dust cover | Universal milling head |

| V axis dust cover | Transformer |

| MPG | Splash guard for rotary table |

| Auto lubrication system | Splash guard for operator |

| Screw chip conveyor | Workpiece measuring device |

| Steel belt chip conveyor with cart | Spindle Quill (W2) 350mm |

CBA-135TR4

| Title | Unit | CBA-135TR4 |

| Spindle |

||

| Main motor (Cont./30min) | kw | 37 / 45 |

| Spindle speed (Max.) | rpm | 2000 |

| Spindle taper | ISO 50 / BT 50 | |

| Spindle diameter | mm | Ø135 |

| Max. spindle torque | Nm | 2150 |

| Travel | ||

| Table cross travel X axis (Horizontal) | mm | 4000 |

| Spindle travel Y axis (Vertical) | mm | 2800 |

| Column moving travel Z axis | mm | 1700 |

| Spindle travel W axis | mm | 700 |

| Distance from spindle nose to table center | mm | 1045 - 2745 |

| Distance from spindle center to table surface | mm | 0 - 2800 |

| Rotary working table | ||

| Table size | mm | 1800 × 2000 |

| T-Slot | mm × No. | 22 × 9 |

| Max. loading weight | kg | 12,000 |

| Min. index | degree | 0.001˚ |

| Max. rotating dia. | mm | 2691 |

| Table rotation speed | rpm | 0.8 |

| Feed | ||

| Rapid(XYZW axis) | mm / min | XY axis=8000 / Z axis=5000 / W axis=3000 |

| Feed rate(X Y Z axis) | mm / min | 1 - 5000 |

| Feed rate(W axis) | mm / min | 1 - 3000 |

| Machine size(L×W×H) | mm | 9550 × 8100 × 6260 |

| Machine weight | Kg | 46000 |

| Controller | Fanuc / Siemens / Heidenhain |

| Standard accessories |

Optional accessories |

| Tool and tool box |

Automatic tool changer |

| Foundation screw and bolt | Work table |

| Spindle oil cooler | Coolant through spindle |

| Spindle counter weight device | Linear scale |

| Working lamp | Spindle support |

| Electro cabinet cooler | Facing head |

| X axis dust cover | Angular milling head |

| Y axis dust cover | Universal milling head |

| V axis dust cover | Transformer |

| MPG | Splash guard for rotary table |

| Auto lubrication system | Splash guard for operator |

| Screw chip conveyor | Workpiece measuring device |

| Steel belt chip conveyor with cart | Spindle Quill (W2) 350mm |