Feature

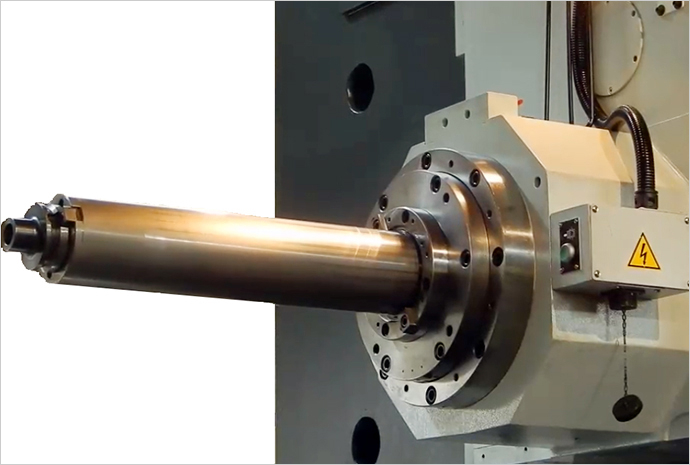

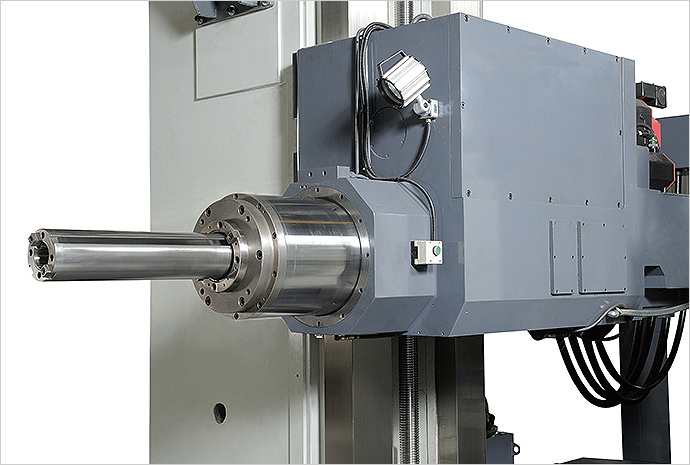

Powerful Spindle 135&150

- The specially designed spindle outer ring cooling system maintains constant bearing accuracy under normal operating conditions.

- This gear type auto-shift design and grease lubrication system also provides superior machine performance and reliability.

- The spindle and boring bar are made of SACM645 alloy. The spindle has been Nitrided to HRC62~68. This hardness maintains spindle form and insures high reliability. This increased rigidity increases the overall machine capability.

- We use the high quality spindle bearings to ensure machine consistency and a longer machine life.

Spindle 135P (without Quill)

Spindle 135Q (without Quill)

Spindle 150Q (with Quill)

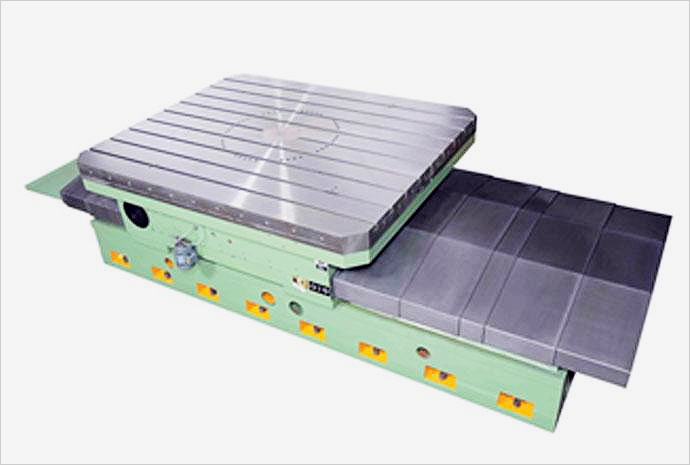

Rotary Working Table

- The bed slideway is box way, adopted roller bearing and worm-gear equipped force lubricated system. Table center equipped Heidenhain rotary encoder assure index accuracy. Table equipped Hydraulic clamping system & positioning pin, assure indexing angle 0°, 90°, 180°, 270° heavy cutting accuracy.

- V axis travel: 1500mm / 2000mm

- Working table size : 1800X2000mm / 2000X2500mm

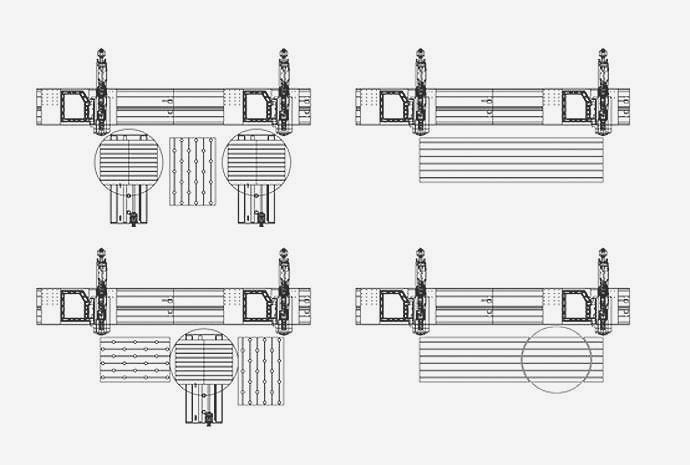

Modular Design Of X Axis Base

- Modular design of X axis base :

The X axis base is modular design which has been planned with different lengths of base. This provides X axis travel combination range from 4M to 10M. - Modular design of X axis transmission system :

X axis travel under 6000mm adopts ball screw driving to increase the feed speed and system stability.

The X axis travel exceeds 6000mm adopts modular high-precision rack and backlash reducer.

CBM-135P

| Specification | Unit | CBM-135P |

| Spindle |

||

| Spindle motor (Cont./30min.) | kw | 37 / 45 |

| Spindle max. speed | rpm | 2000 |

| Spindle taper | ISO-50 / BT-50 | |

| Spindle diameter | mm | Ø135 |

| Spindle end diameter | mm | Ø215 |

| Quill diameter (Z2 axis) | mm | X |

| Spindle max. torque | Nm | 2150 |

| Travel | ||

| Column horizontal travel (X axis) | mm | 4000-6000 : Ball screw Above 6000 : Rack |

| Spindle vertical travel (Y axis) | mm | 2000、2500、3000、3500 |

| Spindle travel (Z1 axis) | mm | 700 |

| Spindle Quill travel (Z2 axis) | mm | X |

| Spindle total travel (Z1+Z2) | mm | 700 |

| Rapid speed | ||

| Rapid speed(X/Y axis) | mm / min | 6000 |

| Rapid speed(Z axis) | mm / min | 3000 |

| Quill speed (Z2 axis) | mm / min | X |

| Standard accessories |

Optional accessories |

| Tool and tool box |

Automatic tool changer |

| Foundation screw and bolt | Coolant through spindle |

| Spindle oil cooler | Linear scale |

| Spindle counter weight device | Spindle support |

| Working lamp | Facing head |

| Electro cabinet cooler | Transformer |

| X axis dust cover | Splash guard for rotary table |

| Y axis dust cover | Splash guard for operator |

| MPG | Workpiece measuring device |

| Auto lubrication system | Rotary table |

| Floor table | |

| Steel belt chip conveyor with cart |

CBM-135QF

| Specification | Unit | CBM-135QF |

| Spindle |

||

| Spindle motor (Cont./30min.) | kw | 37 / 45 |

| Spindle max. speed | rpm | 1200 |

| Spindle taper | ISO-50 / BT-50 | |

| Spindle diameter | mm | Ø135 |

| Spindle end diameter | mm | Ø215 |

| Quill diameter (Z2 axis) | mm | Ø380 |

| Spindle max. torque | Nm | 2150 |

| Travel | ||

| Column horizontal travel (X axis) | mm | 4000-6000 : Ball screw Above 6000 : Rack |

| Spindle vertical travel (Y axis) | mm | 2000、2500、3000、3500 |

| Spindle travel (Z1 axis) | mm | 700 |

| Spindle Quill travel (Z2 axis) | mm | 350 |

| Spindle total travel (Z1+Z2) | mm | 1050 |

| Rapid speed | ||

| Rapid speed(X/Y axis) | mm / min | 6000 |

| Rapid speed(Z axis) | mm / min | 3000 |

| Quill speed (Z2 axis) | mm / min | 1 - 1500 |

| Standard accessories |

Optional accessories |

| Tool and tool box |

Automatic tool changer |

| Foundation screw and bolt | Coolant through spindle |

| Spindle oil cooler | Linear scale |

| Spindle counter weight device | Spindle support |

| Working lamp | Facing head |

| Electro cabinet cooler | Transformer |

| X axis dust cover | Splash guard for rotary table |

| Y axis dust cover | Splash guard for operator |

| MPG | Workpiece measuring device |

| Auto lubrication system | Rotary table |

| Floor table | |

| Steel belt chip conveyor with cart |

CBM-150P

| Specification |

Unit | CBM-150P |

| Spindle |

||

| Spindle motor (Cont./30min.) | kw | 45 / 55 |

| Spindle max. speed | rpm | 1200 |

| Spindle taper | ISO-50 / BT-50 | |

| Spindle diameter | mm | Ø150 |

| Spindle end diameter | mm | Ø250 |

| Quill diameter (Z2 axis) | mm | X |

| Spindle max. torque | Nm | 2620 |

| Travel | ||

| Column horizontal travel (X axis) | mm | 4000-6000 : Ball screw Above 6000 : Rack |

| Spindle vertical travel (Y axis) | mm | 2000、2500、3000、3500 |

| Spindle travel (Z1 axis) | mm | 900 |

| Spindle Quill travel (Z2 axis) | mm | X |

| Spindle total travel (Z1+Z2) | mm | 900 |

| Rapid speed | ||

| Rapid speed(X/Y axis) | mm / min | 6000 |

| Rapid speed(Z axis) | mm / min | 3000 |

| Quill speed (Z2 axis) | mm / min | X |

| Standard accessories |

Optional accessories |

| Tool and tool box |

Automatic tool changer |

| Foundation screw and bolt | Coolant through spindle |

| Spindle oil cooler | Linear scale |

| Spindle counter weight device | Spindle support |

| Working lamp | Facing head |

| Electro cabinet cooler | Transformer |

| X axis dust cover | Splash guard for rotary table |

| Y axis dust cover | Splash guard for operator |

| MPG | Workpiece measuring device |

| Auto lubrication system | Rotary table |

| Floor table | |

| Steel belt chip conveyor with cart |

CBM-150QF

| Specification |

Unit | CBM-150QF |

| Spindle |

||

| Spindle motor (Cont./30min.) | kw | 45 / 55 |

| Spindle max. speed | rpm | 1200 |

| Spindle taper | ISO-50 / BT-50 | |

| Spindle diameter | mm | Ø150 |

| Spindle end diameter | mm | Ø250 |

| Quill diameter (Z2 axis) | mm | Ø380 |

| Spindle max. torque | Nm | 2620 |

| Travel | ||

| Column horizontal travel (X axis) | mm | 4000 - 6000 : Ball screw Above 6000 : Rack |

| Spindle vertical travel (Y axis) | mm | 2000、2500、3000、3500 |

| Spindle travel (Z1 axis) | mm | 900 |

| Spindle Quill travel (Z2 axis) | mm | 400 |

| Spindle total travel (Z1+Z2) | mm | 1300 |

| Rapid speed | ||

| Rapid speed(X/Y axis) | mm / min | 6000 |

| Rapid speed(Z axis) | mm / min | 3000 |

| Quill speed (Z2 axis) | mm / min | 1 - 1500 |

| Standard accessories |

Optional accessories |

| Tool and tool box |

Automatic tool changer |

| Foundation screw and bolt | Coolant through spindle |

| Spindle oil cooler | Linear scale |

| Spindle counter weight device | Spindle support |

| Working lamp | Facing head |

| Electro cabinet cooler | Transformer |

| X axis dust cover | Splash guard for rotary table |

| Y axis dust cover | Splash guard for operator |

| MPG | Workpiece measuring device |

| Auto lubrication system | Rotary table |

| Floor table | |

| Steel belt chip conveyor with cart |