Feature

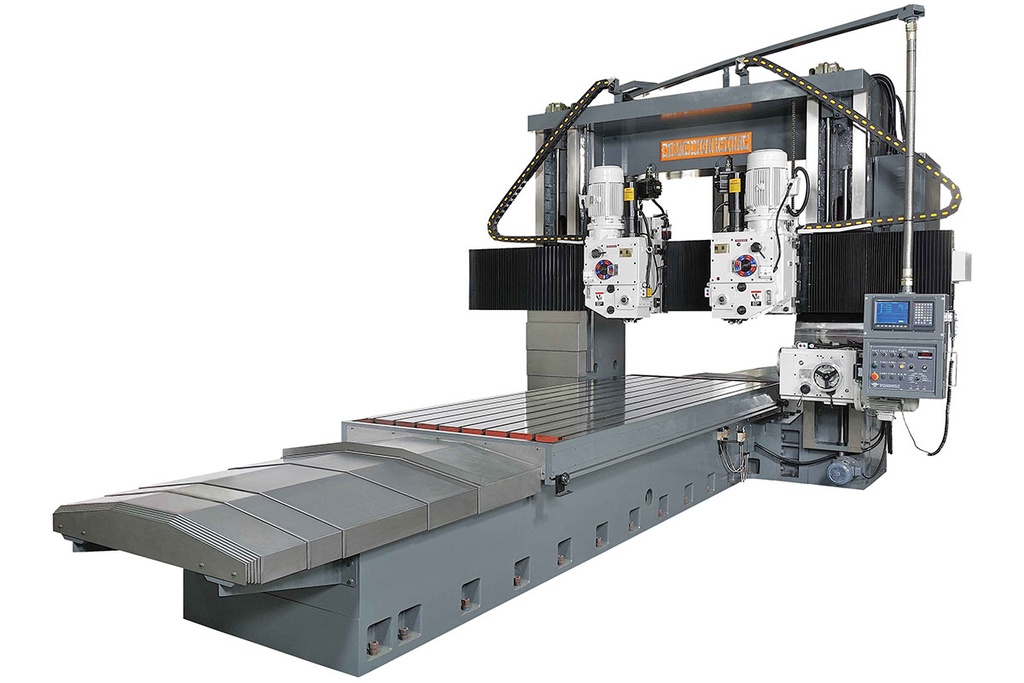

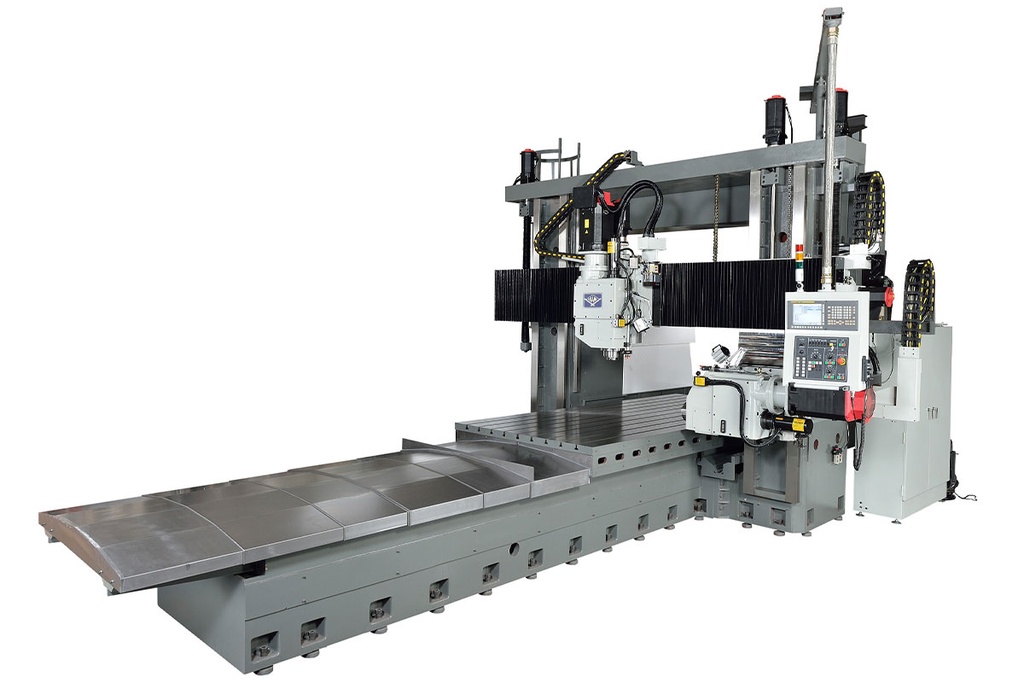

Heavy Duty Double Housing Milling Machine

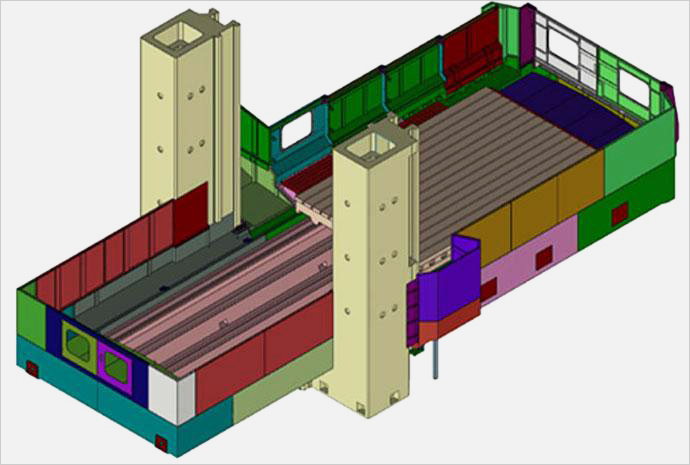

- High Rigid Box Way Structure:Casting iron material FC 30, Heat-Treat for stress relief and increase the stability.

- Box Way casting for Bed Structure to enhance the stability and rigidity.

- Single V type and single box slide way for base structure. Box way casting for the column and cross rail.

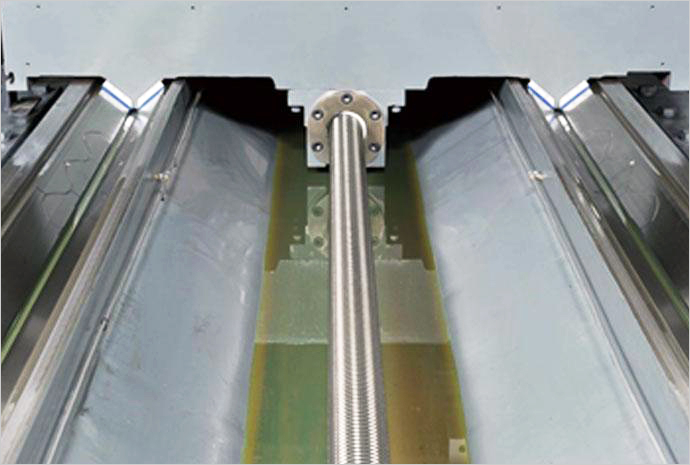

- Ball Screw or Rack are used for the work table.

- Auto Lubrication system for the slide way.

- Powerful spindle is perfectly suitable for the heavy cutting.

Manual spindle

Servo spindle

Splash guard (option)

CP-160 / CP-200 / CP-250 / CP-300

| Specification |

Unit | CP-160 | CP-200 | CP-250 | CP-300 |

| Cutting length (X axis) | mm |

|

|

|

|

| Cutting width (Y axis) | mm | 1750 | 2150 | 2650 | 3150 |

| Cross rail vertical travel(W axis) | mm | 1300 | 1500 | 2000 | 2500 |

| Horizontal spindle vertical travel (U axis) | mm | 850 | 1050 | 1500 | 2500 |

| Distance between columns | mm | 1750 | 2150 | 2650 | 3150 |

| Working table size (L×W) | mm |

|

|

|

|

| T slot | 22mm × 7 | 22mm × 9 | 28mm × 11 | 28mm × 13 | |

| Working table loading | kg |

|

|

|

|

| controller | PLC / Optional : Fanuc | PLC / Optional : Fanuc | PLC / Optional : Fanuc | PLC / Optional : Fanuc | |

| Machine length | mm |

|

|

|

|

| Machine width | mm | 3870 | 4570 | 5400 | 5910 |

| Machine height | mm | 3830 | 4150 | 4800 | 5450 |

| Machine weight | kg |

|

|

|

|

| Use spindle model | CL-09 CMH-20 CMH-25 CMH-30 CMH-NC | CL-09 CMH-20 CMH-25 CMH-30 CMH-NC | CL-09 CMH-20 CMH-25 CMH-30 CMH-NC | CL-09 CMH-20 CMH-25 CMH-30 CMH-NC |

| Specification |

Unit | CL-09 | CMH-20 | CMH-25 | CMH-30 | CMH-NC |

| Spindle motor | 15HP / 4P | 20HP / 4P | 25HP / 4P | 30HP / 4P | Inverter motor 30HP | |

| Spindle taper | NT-50 / BT-50 | NT-50 / BT-50 | NT-50 / BT-50 | NT-50 / BT-50 | NT-50 / BT-50 | |

| Spindle diameter | mm | 128.57 | 128.57 | 128.57 | 128.57 | 128.57 |

| Spindle travel | mm | 380 | 400 | 400 | 400 | 400 |

| Spindle quill diameter | mm | × | 200 | 200 | 200 | × |

| Spindle quill travel | mm | × | 130 | 130 | 130 | × |

| Spindle speed | rpm | 50HZ: 66,83,116,166, 216,291,375,493,662 60HZ: 80,100,140,200, 260,350,450,592,795 | 50HZ: 58,76,112,152, 208, 272,404,548 60HZ: 68,90,136,184,250,330,488,656 | 50HZ: 58,76,112,152, 208,272,404,548 60HZ: 68,90,136,184,250,330,488,656 | 50HZ: 58,76,112,152, 208,272,404,548 60HZ: 68,90,136,184,250,330,488,656 | 250-750 rpm |

| Steps of spindle speeds | 9 | 8 | 8 | 8 | Variable | |

| Max. face cutter diameter | mm | 200 | 250 | 250 | 250 | 250 |

| Weight | kg | 550 | 1070 | 1100 | 1150 | 1150 |

| Standard Accessories |

Optional Accessories |

| Tools and tool box |

Angular milling head (manual type) |

| Foundation screw and bolt | Air power draw-bar NT-50 / BT-50 |

| X axis dust cover | Linear scale |

| Y axis dust cover | Pneumatic rotary working table |

| Auto lubrication system for working table | Magnetic chuck |

| Fanuc controller |